FLUORITE - FLUORSPAR

What is Fluorite (Fluorspar)?

Fluorite, that is often called fluorspar in the trade, is a mineral with a combination of Calcium and Fluoride (Calcium Fluoride CaF2). This name is derived from the Latin word Fluor (to flow) and is related to its low melting point and its initial use in metallurgy as a flux. Fluorite lumps exist in nature and are extracted from various mines around the world and used in various industries after processing. Fluorite was used for decorative purposes such as vases, cups and decorative dishes by the Greeks and Romans. The use of fluorite as a flux was discovered in the 16th century and flourished with the growth of steel, aluminum, chemical and ceramic industries, especially during the First and Second World Wars.

Application of Fluorite

Fluorite in the hydrofluoric acid industry

The acid is a catalyst for the production of alkylate, a substance that is considered important in high-octane fuel for airplanes and piston-driven automobiles, in steel pickling, deglazing and etching and polishing of glass, and in various electroplating operations.

Fluorite in the metallurgical industry

Fluorite or fluorspar is sometimes used as a flux along with lime to improve the fluidity of slag in steelmaking and metallurgical processes. Fluorite improves the fluidity of the slag (by lowering its melting point) and, as a result, makes it possible to remove sulfur and phosphorus from the steel into the slag. The consumption of fluorspar in steel production is 2 to 10 kg or 5 to 10% of the amount of additional lime. Fluorite is used in the refinement of electric slag with a ratio of 70 to 30 fluorite to lime. The goal in refining electrical slag is to form highly conductive slag with the required melting temperature. In aluminum smelting, about 23 kg of AlF3 is used equivalent per ton of aluminum. Fluorite serves similar purposes in iron foundries, where 7-9 kg per ton of molten metal is added to the load of the smelting furnace.Fluorite (fluorspar) in the cement industry

Fluorite is used as a flux in cement production. This material is added to the mixture of cement raw materials before entering the rotary furnace; The addition of this mineral causes the furnace to operate at a low temperature and thus is economically affordable. Fluorite helps to produce a softer clinker product that is easier to crush and thus leads to an increase in electrical energy.Fluorite (Fluorspar) in the glass industry

Fluorite is used in the glass industry to make flint glass, white or milky glass, and glazes. Flint glass mixtures usually contain 3% fluorite. Milk bottles contain 10-20% fluorite and are used in antique glass containers, sanitary ware and restaurants. Opaque glazes are used to cover stoves, refrigerators, cabinets, bathtubs, and cooking utensils, and to work on bricks, tiles, and other building materials.Fluorite coating of the welding electrode

Alkaline electrodes have calcium fluoride (Fluorespar) in their coating. The decomposition of calcium carbonate forms carbon dioxide and carbon monoxide, which protects the arc from contamination, and as a result, a small amount of sulfur and oxygen remains in the weld metal. Therefore, the strength and toughness of this weld is one of the strongest welds produced by this type of electrode, and its resistance to cracking is also higher. Alkaline electrodes produce a lower melting point slag than rutile and acid electrodes. This company produces fluorite with a grade of 97%, especially for use in the coating of welding electrodes. Contact us to buy and get more information.Other applications of fluorite

Ceramic grade fluorite has been used in the production of magnesium and calcium metals and in the preparation of some manganese chemicals. In current industrial operations, consumers prefer to buy acidic fluorite instead of ceramic grade and dilute it properly. Fluorite with ceramic and metallurgical grade may be used in the manufacture of fiber glass insulation, in melting zinc, as inhibitors of green vanadium in pea -color brick production as abrasives on certain types of sandpapers. Different fluorite grade is used in the production of calcium carbide in the electrical furnace, making electrodes, for arc lamps and as a connection material for sanding wheels. Fluorite has been used in the production of magnesium and calcium metals and in the preparation of some manganese chemicals.Fluorspar Acid or chemical grade:

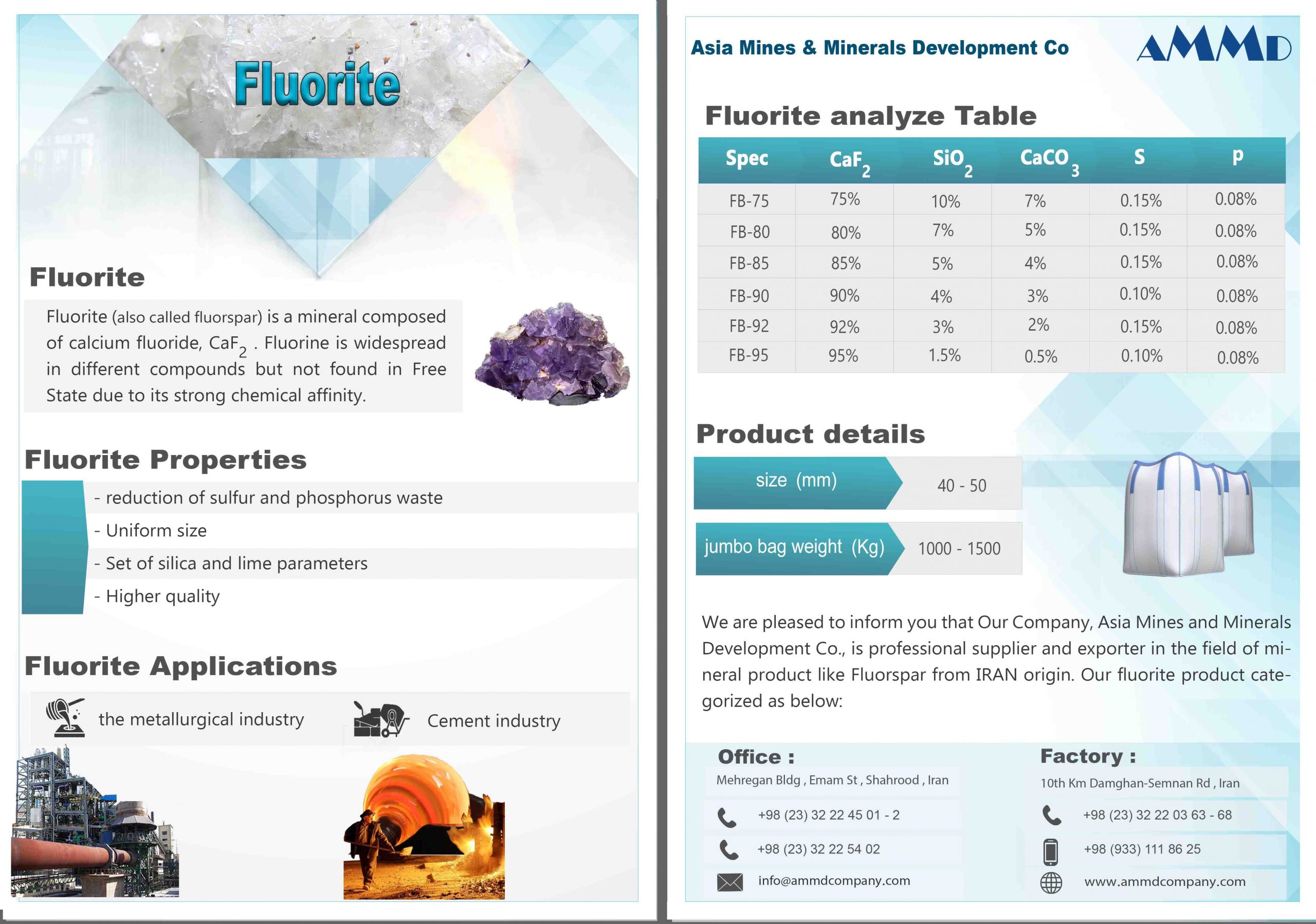

This grade of fluorite ideally contains a minimum of 97% CaF2 and up to 1.5% SiO2. For ordinary products, however, 93% CaF2 is acceptable as in Iran.

This grade of fluorite ideally contains a minimum of 97% CaF2 and up to 1.5% SiO2. For ordinary products, however, 93% CaF2 is acceptable as in Iran.

Fluorspar Ceramic grade:

For high-quality ceramic products, fluorite containing a minimum of 95% CaF2, up to 2.5% SiO2 and up to 1.5% CaCO3 is generally considered standard in Iran. But strictly speaking, there is no standard grade and it is highly variable depending on the quality of the finished product, and for very ordinary cheap products, low-grade fluorite can also be used.

For high-quality ceramic products, fluorite containing a minimum of 95% CaF2, up to 2.5% SiO2 and up to 1.5% CaCO3 is generally considered standard in Iran. But strictly speaking, there is no standard grade and it is highly variable depending on the quality of the finished product, and for very ordinary cheap products, low-grade fluorite can also be used.

Fluorspar Metallurgical grade:

This grade is expressed in terms of what is called effective units of CaF2. Effective CaF2 is determined by subtracting 2.5 units for every unit of SiO2. Determined thus, the effective CaF2 be at least 60 percent, which is the same as 80% CaF2 and 8% SiO2. But the maximum grade can go beyond 97% CaF2 with a maximum of 1% SiO2.

This grade is expressed in terms of what is called effective units of CaF2. Effective CaF2 is determined by subtracting 2.5 units for every unit of SiO2. Determined thus, the effective CaF2 be at least 60 percent, which is the same as 80% CaF2 and 8% SiO2. But the maximum grade can go beyond 97% CaF2 with a maximum of 1% SiO2.

USES AND SPECIFICATIONS

Fluorite has few primary uses, one of which is hydrofluoric acid. There is a number of uses of this acid and its derivatives. The principal uses are therefore grouped under those based on the primary mineral fluorite, those on its principal derivative hydrofluoric acid, those on the latter’s derivative fluorine gas and those based on a mix of these. They are:A. Uses based directly on fluorite

1. Flux in metallurgy

2. Ceramics

3. Enamel

4. Optics

5. Cement

6. Gem

7. Hydrofluoric acid

B. Uses based on hydrofluoric acid

1. Chemicals

(a) Synthetic cryolite

(b) Fluoro-silicic acid

(c) Aluminum fluoride

(d) Chloro-fluoro-carbons

(e) Potassium fluoride

(f) Fluoro-boric acid

(g) Fluorine gas

2. Industrial processes

(a) Aluminium metallurgy

(b) Niobium-tantalum metallurgy

(c) High-octane petroleum

1. Chemicals

(a) Synthetic cryolite

(b) Fluoro-silicic acid

(c) Aluminum fluoride

(d) Chloro-fluoro-carbons

(e) Potassium fluoride

(f) Fluoro-boric acid

(g) Fluorine gas

2. Industrial processes

(a) Aluminium metallurgy

(b) Niobium-tantalum metallurgy

(c) High-octane petroleum

C. Chemicals and processes based on fluorine

1. Potassium perchlorate

2. Anhydrous hydrogen fluoride

3. Sodium silico-fluoride

4. Uranium hexafluoride

5. Fluoro-silicates of ammonium, magnesium and zinc

6. Fluoro-carbon

7. Fluoro-polymer

8. Sodium fluoride

9. Stannous fluoride

10. Sodium mono-fluoro-phosphate

11. Uranium metallurgy

1. Potassium perchlorate

2. Anhydrous hydrogen fluoride

3. Sodium silico-fluoride

4. Uranium hexafluoride

5. Fluoro-silicates of ammonium, magnesium and zinc

6. Fluoro-carbon

7. Fluoro-polymer

8. Sodium fluoride

9. Stannous fluoride

10. Sodium mono-fluoro-phosphate

11. Uranium metallurgy

D. Uses based on a mix

1. Glass

1. Glass

Fluorite or fluorspar briquette factory in Iran

AMMD Co has the largest fluorite concentrate and briquette production factory in Iran with a capacity of 15,000 tons per year. Fluorite briquettes are widely used in steel factories and metallurgy of non-ferrous metals and alloy metals and chemical industries due to better grade control and reduction of sulfur and phosphorus wastes and uniform granulation and size. In the fluorite briquettes produced by this company, the amount of silica and lime parameters is controlled, which helps to improve the quality of the product. In general, the use of fluorite briquettes is more cost-effective compared to crushed lumps from mines. The diversity in the quality of fluorine briquettes and its processing has caused this company to produce a wide range of products with a calcium fluoride content of 65 to 95% and provide them to consumers. They are packaged and stored in product warehouses.AMMD Co fluorspar export destination

The export destinations of fluorite from Iran are mainly Turkey, India, Taiwan, Iraq, Armenia, Azerbaijan, Oman, Turkmenistan, Belgium, Russia and Georgia. Of these, Turkey has been the largest export destination of fluorite from Iran. According to statistics, fluorite reserves in the world are estimated at 500 million tons. The annual production of fluorite in the world has reached about 5.8 million tons and the main producing countries in the world are the People’s of China, Mexico, South Africa, Mongolia, Vietnam and Spain. According to the available statistics of these countries in 2018, the amount They account for 95% of the total fluorite production. Considering the reserves available in the country and the existing potentials of mineral extraction and processing, Iran’s share of one percent of the world production is very small and this amount should be increased.Selling all type of fluorspar

Asia Mines and Minerals Development Company provides all types of acidic, ceramic and metallurgical fluorites. Fluorspar of this company is used in acid grade, hydrofluoric acid, casting, electrode making, steel making and glazing industries. Fluorspar is one of the export products of this company, which has been exported to Russia, China, India, Turkey and Tajikistan. The fluorite stone produced by this company is available to our valued customers with the highest quality and the cheapest price. The price of fluorite stone depends on its granulation and the quality of calcium fluoride in it, as well as the percentage of harmful elements and compounds such as silica, sulfur and phosphorus. Get in touch with us to buy fluorspar and inquire about the price of fluorite and get more information.